|

|||||

|

|

Overall, the fluid transfer in the dairy factories is done by the pumps. Accordingly, centrifugal pumps are widely used in dairy industry. The centrifugal pumps consist of primarily of an impeller rotating in a pump casing, a delivery chamber and an electric drive. The impeller generally consist of a number of vanes that, together with the casing, form closed channels for the liquid. The liquid enters the pump axially at the center of the casing and is carried round by the vanes at a speed that becomes progressively higher as the liquid is forced outwards along the vanes. It is the then discharged into the delivery chamber of the pump casing with a high kinetic energy, imparted by the vanes. In the chamber this energy is partly converted into pressure energy a discharge pressure is imparted to the liquid. The energy transmitted from the pump motor, via the impeller, to the liquid is converted into kinetic energy and pressure energy. |

|||

|

|||||

| Services | Click for more information | ||||

|

|||||

|

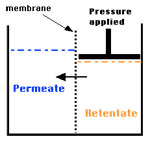

Separation processes such as ultrafiltration (UF), reverse osmosis (RO) are being used more and more in the dairy industry. They compete with conventional processes such as evaporation, distillation and absorption. The advantages of the membrane techniques are mainly that the concentration takes place at low temperatures and without changing the state of aggregation. In the membrane processes the solution with the material to be separated diffuses or flows through different types of membranes. In the processes the solution is forced through the membrane under pressure and particles with a sufficiently high molecular weight are separated. Ultrafiltration, or UF, can be used for dividing whey into one protein-rich fraction and one fraction poor in protein, known as concentrate and ultrafiltrate respectively. As it was mentioned, separation takes place under pressure through a thin membrane which allows the smaller constituents of the whey (minerals) to pass while the large molecules (proteins) are retained. The liquid that, after UF, contains the separated, high-molecular material is called concentrate, or retentate, and the clarified liquid that passes the membrane is called ultrafiltrate or permeate. The membrane is made of a synthetic, polymeric material and the filtering properties vary with material composition and porosity. The product pressure required is determined by the membrane and is max.

|

||||

|

|||||

|

|||||

| Services | Click for more information | ||||

| <<PREVIOUS | NEXT>> | ||||

| فارسی - English | |||||